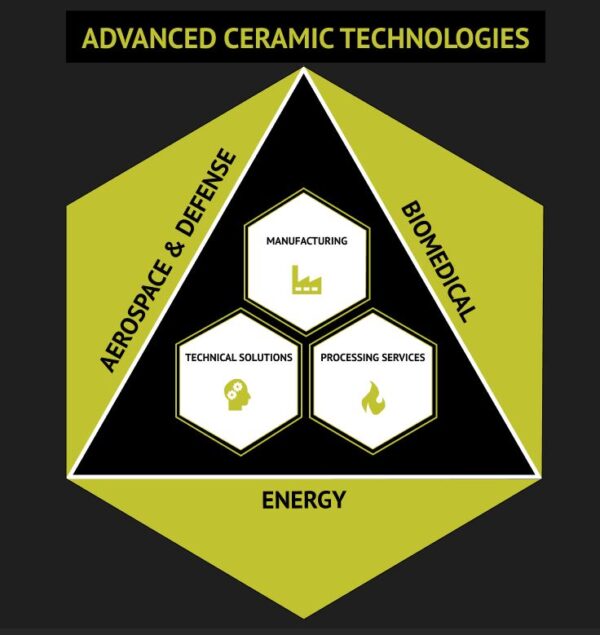

We provide comprehensive advanced ceramic technology solutions across a wide range of industries. We draw upon our strengths in innovation, quality, and advanced manufacturing. These strengths have been distilled from our origins developing technical ceramic and composite components for biomedical, aerospace, defense, and energy markets.

We have an FDA and ANVISA registered manufacturing facility. Our Quality Management System is certified to ISO 13485:2016 and AS9100D.

SINTX is publicly traded on the NASDAQ (SINT).