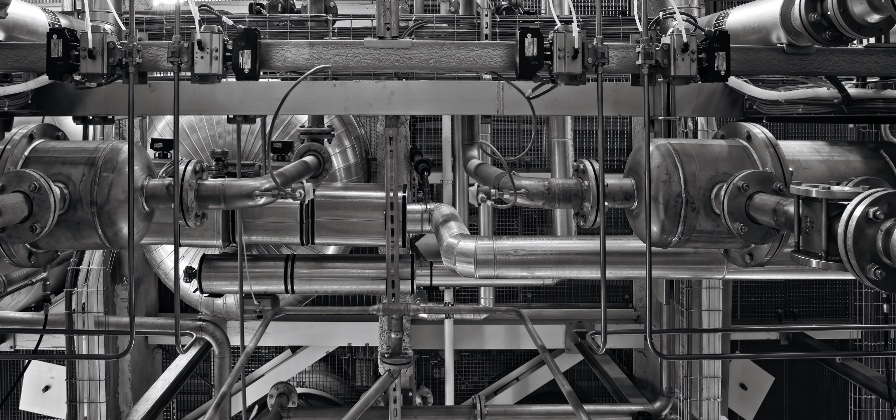

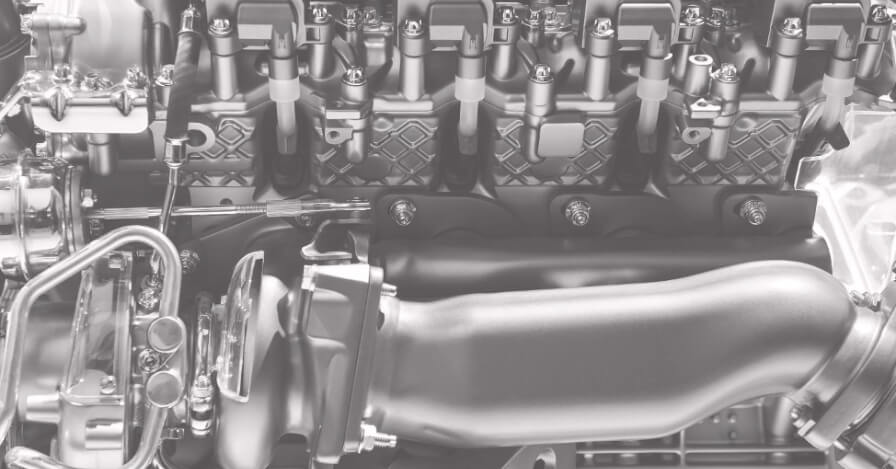

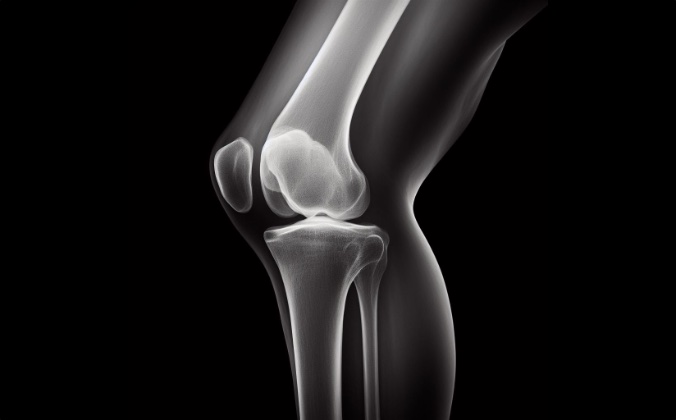

Silicon nitride is an advanced ceramic with a unique set of properties that make it ideal for use in both biomedical and industrial applications. Silicon nitride can be adapted to many different forms and characterizations depending on the application it’s being manufactured for and is often chosen for its ability to outperform other ceramics.

SINTX Technologies is a global leader in the manufacture of silicon nitride components for both the industrial and biomedical sectors.