Thermogravimetric Analysis: A Vital Tool for Processing Technical Ceramics

Thermogravimetric analysis or thermal gravimetric analysis (TGA), is a technique used in ceramic processing and sintering to identify critical temperatures at which a material begins to deteriorate. This data is vital for researchers and process engineers to design and develop successful technical ceramic components.

Processing Ceramics

Ceramic Sintering Process

In processing technical ceramics, inorganic powders are combined with organic processing aids such as binders, lubricants, plasticizers, and dispersants. These organics are necessary to improve the rheological properties of the slurry and pressability of the powder blend for forming low-density parts called green bodies. Green bodies are then further densified using high heat in a process called “sintering.” The dispersants and pressing lubricants are removed prior to sintering to avoid unwanted reactions at the associated high temperatures and/or to ensure the elements do not become part of the final product. The inorganic components remain and become a permanent part of the final product.

Thermal Debinding Process

The most common method for removing organics from a green body is to burn them out in a furnace. This process is sometimes referred to as “thermal debinding.” At higher and higher temperatures, organic molecules begin to break into smaller molecules. Eventually, these molecules become small gas molecules that can leave the green body ceramic. Organic removal can be a delicate process. If gases volatilize rapidly, they can build up and produce cracks and defects in the final product.

Advantages of Thermogravimetric Analysis For Ceramic Processing

Thermogravimetric analysis is a materials characterization technique where sample mass is precisely recorded during heating. This simple experiment can identify critical temperatures at which a material begins to degrade, evaporate, or oxidize. TGA analysis gives researchers and process engineers the information required to design furnace temperature profiles for binder removal, ensuring the integrity of the final ceramic component isn’t compromised during this process

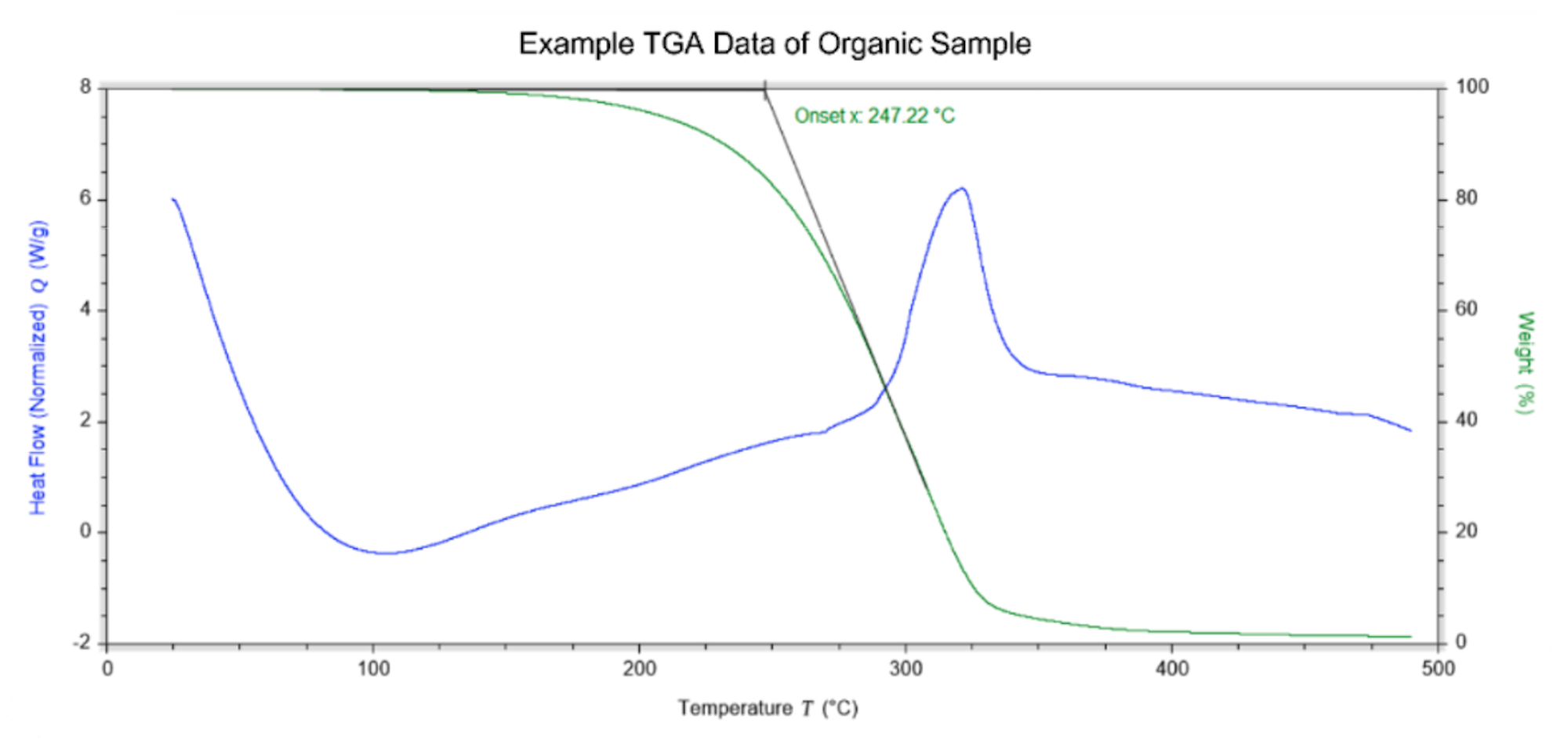

Figure 1 – TGA dataset for an organic sample heated to 500ºC in air

Figure 1 – TGA dataset for an organic sample heated to 500ºC in air

Figure 1. displays an example of a TGA dataset. The degradation onset temperature is calculated and represents where the weight of the sample begins to steadily decrease. The heat flow in and out of the sample corresponds to the breaking of bonds in the sample and can also be used to differentiate between a chemical reaction and physical change in the sample. To know the rate at which organic mass is volatilized, we find the first derivative of the wt% curve. The onset temperature can also be estimated using this plot as shown. Note that TGA analysis cannot identify specific products of thermal degradation.

TGA analysis can also show a material mass gain such as a material undergoing oxidation. Adding oxygen atoms increases the sample’s mass. TGA analysis instruments use highly sensitive mass balances that can detect this minute increase in weight. Knowing when a material oxidizes is useful information for adapting a process to avoid any unwanted material changes.

Thermogravimetric analysis provides actionable data for process parameter selection in validating a production process or for material selection in researching new ceramic materials synthesis.

OEM Partnership with SINTX

SINTX is a flexible partner that utilizes thermogravimetric analysis among other manufacturing techniques to ensure the integrity and performance of the technical ceramic components we help fabricate. Our unrivaled in-house manufacturing capabilities allow for intricate designs and shapes that can be rapidly developed, prototyped, and tested across a wide variety of applications, such as armor and aerospace. Our leading R&D and manufacturing teams have years of experience processing high-performance technical ceramics. Contact SINTX to get started.

Learn more

Learn more