SINTX’s Capabilities to Manufacture Complex Shapes

Ceramics can survive extreme temperatures and corrosive environments that destroy metals or plastics. They are extremely hard and stiff, offering an overall longer life in many applications. Many ceramics offer outstanding performance as an electronic substrate since they can be both electrically insulative and thermally conductive at the same time, which is not possible with metals (electrically conductive) or plastics (thermally insulative). Ceramics can also be engineered to be as strong as metals and outperform metals in many mechanically demanding applications.

But manufacturability is key issue with most ceramics. While there are numerous ways ceramics can be formed, fired, and finished to meet the needs of a given application, they are often much more difficult to fabricate as compared to plastics or metals. Today, ceramic manufacturing has advanced to enable solutions that meet very tight tolerances.

At SINTX, we have the ability to manufacture complex shapes with special features and textures; we have nearly 20 years of experience in manufacturing silicon nitride. We excel at green machining of silicon nitride doing most of the work in the green state, reducing or eliminating any hard grinding. We use peck drilling with capabilities for micro through holes as small as 0.40 mm. We also have CNC, lathe, & surface grinding capabilities. We can machine fully densified thread forms within standard metric and unified threads.

SINTX also does laser texturing. We have added several forms of micro surface texturing to our silicon nitride components. Laser texture can accommodate flat, round and more complicated surfaces. We can develop custom texture patterns to meet your design requirements.

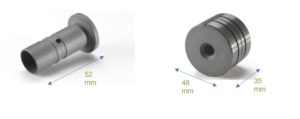

Some examples of our shapes produced by green machining and laser texturing.

Learn more

Learn more